According to the drawings, samples or personalized needs provided by customers, we use CNC milling machines and CNC lathes to provide customized production processing services for various metal materials and plastic materials.

The core is "customization on demand, precision processing", which is different from batch standard parts processing and emphasizes non-standard, personalized, small batch or single piece processing mode.

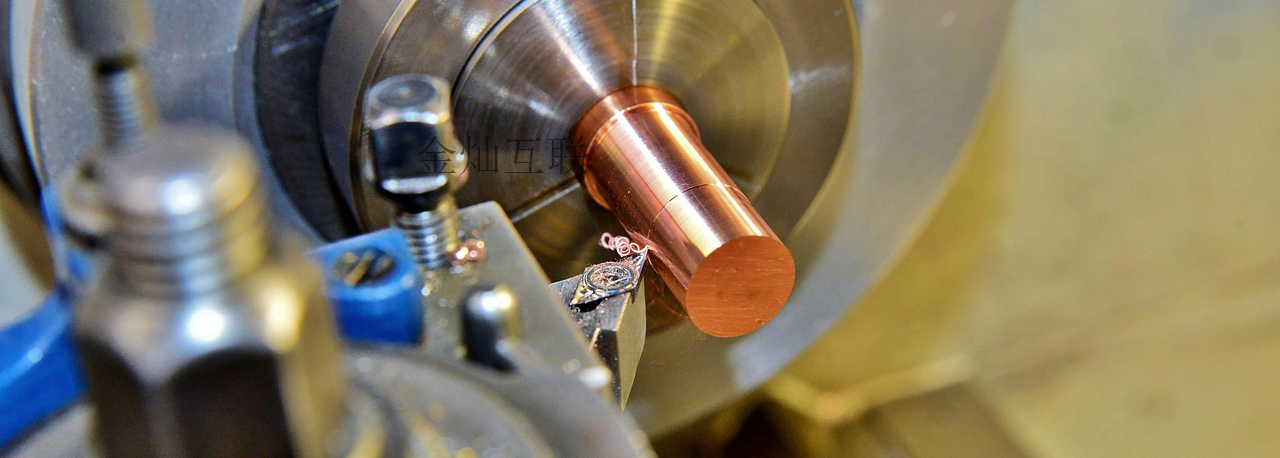

Good machining surface quality

After the use of high-performance tools and coolants, CNC machining can obtain good surface finish, reduce the need for subsequent secondary processing such as polishing and grinding, and improve overall efficiency.

Efficient realization of complex structures

Automation and intelligence

With the programming function of the CNC system, machining parts can achieve unmanned processing and multi-process linkage, greatly improving the degree of production automation. At the same time, the advanced monitoring system can detect the processing status in real time and realize intelligent management such as early warning, deviation correction and data collection.

Drilling

Use CNC lathes for basic machining operations such as external circles, internal holes, end faces, and threads

For parts with planes, slots or special-shaped structures, vertical or horizontal CNC milling machines can be used to achieve the machining of complex geometric contours

Open precision holes on parts, and improve the dimensional accuracy and position accuracy of holes by boring.

For parts with extremely high surface roughness requirements, CNC grinders can be used to finely grind cylindrical surfaces, internal holes, end faces and other parts.

Used to process locations that are difficult for conventional tools to reach, such as deep cavities, fine slits and other complex structures.

Quenching, annealing, and nitriding to enhance their hardness, wear resistance and corrosion resistance; Electroplating and anodizing are used to improve appearance and service life.

Program tool paths according to the drawings provided by customers, and generate programming for CNC machine tools.

Select appropriate metal materials according to design requirements, such as aluminum alloy, stainless steel, carbon steel, brass, titanium alloy, plastic ABS, POM, etc.

Execute the program on the CNC equipment and complete various machining tasks step by step according to the set process, including turning, milling, drilling and other operations.

Perform necessary surface treatment processes according to the purpose of the prototype parts, such as: painting, powder coating, electroplating, anodizing, etc.

Finally, the CMM detector is used for dimensional inspection and appearance inspection. After passing the inspection, the parts are classified and packaged before being sent to customer