According to the product design, 3D model or functional requirements provided by the customer, the plastic particles are melted and injected into the mold for cooling and molding by opening the mold and using injection molding equipment to realize the production method of personalized, non-standard or small-batch customized plastic products.

According to the product design, 3D model or functional requirements provided by the customer, the plastic particles are melted and injected into the mold for cooling and molding by opening the mold and using injection molding equipment to realize the production method of personalized, non-standard or small-batch customized plastic products.

It combines the high efficiency of traditional injection molding with the flexible customization capabilities of modern manufacturing, and is one of the main ways to customize industrial plastic parts.

Product design stage

Receive 2D/3D drawings (STEP, IGS, DWG, PDF, etc.) provided by customers

Perform DFM manufacture ability assessment: including draft angle, wall thickness uniformity, rib position design, etc.

Provide structural optimization suggestions to ensure that the design is suitable for injection molding.

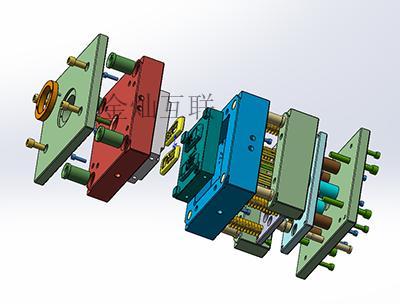

Mold manufacturing

Use high-quality mold steel (S136, 718, NAK80, P20, etc.)

CNC + EDM processing to ensure mold accuracy and durability

Standard mold frame, support fast mold change and multi-cavity design

Reasonably match hot runner/cold runner design according to product and output

Injection molding

Use fully automatic injection molding machines (50T~500T), covering small to medium and large injection molded parts

Control temperature, pressure and holding time to achieve stable output of high-quality injection molded parts

Can perform special processes such as two-color injection molding, insert injection molding and transparent injection molding

ABS has both rigidity and toughness, good impact resistance and durability, and can be used for a long time under medium load.

ABS has a high surface gloss and can be directly subjected to surface treatment processes such as spray painting and silk screen printing. It is suitable for decorative parts and panel parts.

Execute the program on the CNC equipment and complete various machining tasks step by step according to the set process, including turning, milling, drilling and other operations.

Perform necessary surface treatment processes according to the purpose of the prototype parts, such as: painting, powder coating, electroplating, anodizing, etc.

ABS has a temperature resistance of up to 85~100°C, which can be further increased to above 120°C after modification.

Customization services:

1. Support customized colors (Pantone color numbers)

Surface treatment: spray painting, electroplating, UV, rubber oil, polishing

2. Support special structural designs such as metal inserts, transparent inserts, and rubber encapsulation

3. Support small batch rapid proofing, and can also support mass production to support million-level delivery

4. Logo engraving, electroprinting, laser engraving and other personalized logos can be integrated into the mold