Aluminum alloy and zinc alloy die castings have been widely used in various mid-to-high-end manufacturing scenarios due to their comprehensive advantages of high efficiency, high strength and high aesthetics.

Aluminum alloy and zinc alloy die castings have been widely used in various mid-to-high-end manufacturing scenarios due to their comprehensive advantages of high efficiency, high strength and high aesthetics.

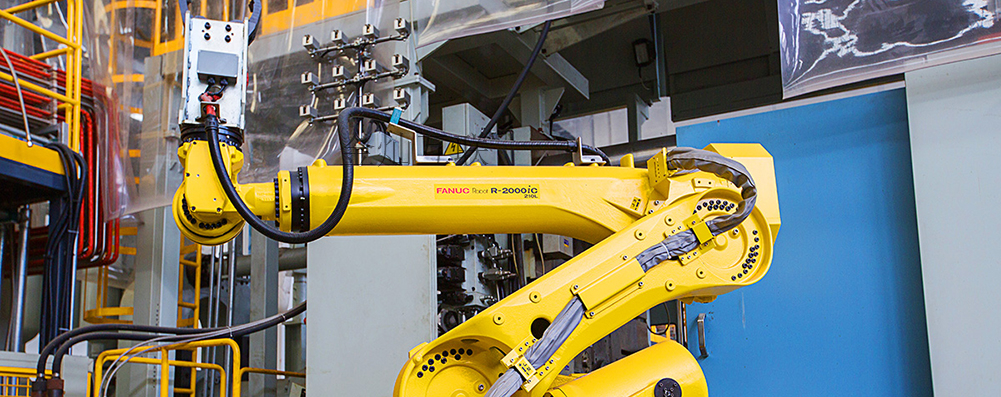

Vallo provides customers with stable, cost-effective and customized die casting overall solutions with rich die casting and finishing experience, perfect quality system and flexible delivery capabilities.

| Material Model | Features | Application direction |

ADC12(A383) | Good casting performance, strong corrosion resistance, excellent electrical performance | General type, electronic, electrical, mechanical housing | |

A380 | Good comprehensive performance and compressive strength | High-strength structural parts, radiators, automotive accessories | |

A360 | High temperature resistance, good thermal conductivity | High-temperature components, automotive engine housing, etc. | |

6061/6082 | Higher strength after die casting | Military, industrial automation equipment components |

| Material model | Features | Application direction |

Zamak 3(ZA3) | Good formability, stable dimensions, easy electroplating | Small structural parts, electronic accessories, hardware decorative parts | |

Zamak 5(ZA5) | High strength and hardness, suitable for load-bearing parts | Door locks, connectors, mechanical transmission parts | |

ZL0410、ZL0430 | Corrosion resistance, excellent electroplating performance | Mobile phone housing, decorative parts, high-gloss parts |

--The die-casting production cycle is short, suitable for medium and large batch manufacturing of thousands to hundreds of thousands of pieces;

--Long mold life, unit cost significantly reduced with the increase of batch.

--Achieve dimensional accuracy of ±0.05mm;

--High repeatability, strong consistency of molded parts, suitable for assembly and batch assembly.

--Aluminum alloy: light weight, high strength, corrosion resistance, excellent thermal conductivity;

--Zinc alloy: high density, suitable for high-strength small parts.

--The surface of aluminum alloy die-castings can be anodized, sandblasted, painted, and laser engraved;

--Zinc alloy parts support decorative treatments such as electroplating, baking varnish, UV, and high-gloss polishing.

Standard production process

1. The engineering team conducts drawing review and structural evaluation, and issues DFM analysis according to 3D drawings;

2. Customize molds according to product structure, including mold frame, core, and cooling system design;

3. Use high-pressure die-casting machine to inject molten metal for die-casting, Short molding time, high precision, and excellent strength consistency;

4. If there are high-precision holes, threads, and tolerance surfaces, perform CNC secondary finishing or tapping;

5. Aluminum parts support anodizing, electrophoresis, spraying, sandblasting, and laser engraving; Zinc parts support electroplating (nickel/ chromium/ gold color, etc.), PU coating, and polishing;